1. Adopt advanced energy-saving technology

Another way to save energy, improve melting quality, and prolong the use of energy-saving furnaces is to increase the amount of broken glass, and the amount of foreign broken glass added reaches 60%-70%. The ideal is to use 100% cullet to achieve the goal of "ecological" glass production. Realize the vertical development of energy saving and environmental protection!

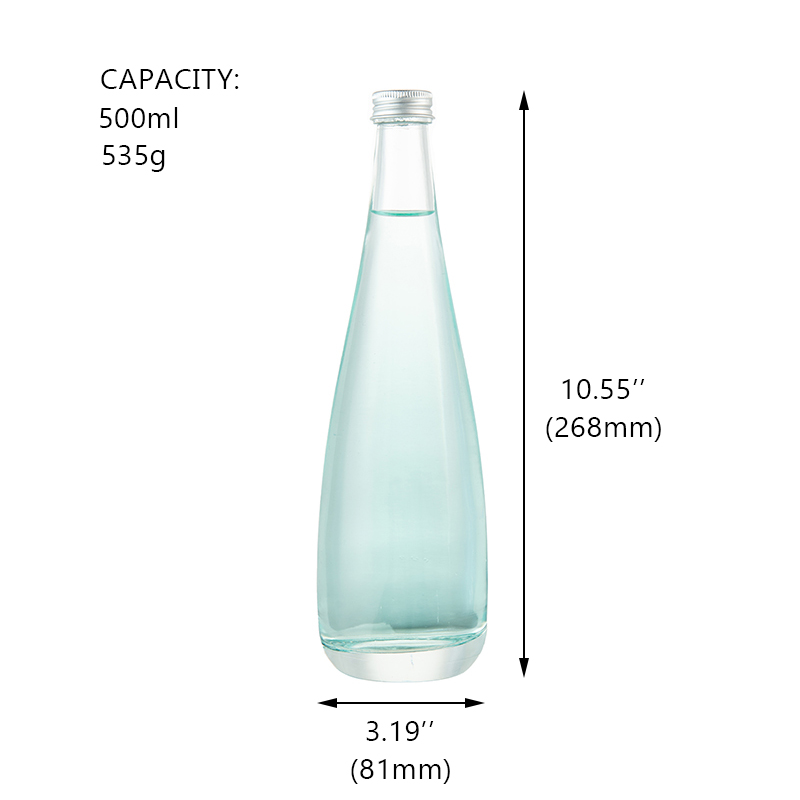

2. Lightweight glass jars

In developed countries such as Europe, America and Japan, lightweight bottles have become the leading products of glass bottles. 80% of the glass bottles and jars produced by Obedand Company in Germany are lightweight disposable bottles. The precise control of raw material composition, the precise control of the whole melting process, the small mouth pressure blowing technology (NNPB), the spraying of the hot and cold ends of bottles and cans, and the on-line inspection are the fundamental guarantees for realizing the lightweight of bottles and cans. Some countries are developing new surface enhancement technologies for bottles and cans in an attempt to further reduce the weight of bottles and cans. For example, Germany Heye Co., Ltd. coats a thin layer of organic resin on the surface of the bottle wall to produce a 1-liter concentrated juice bottle with only 295 grams, which can prevent the glass bottle from being scratched, thereby increasing the pressure strength of the bottle by 20%. The current popular plastic film sleeve label is also conducive to the lightweight of glass bottles.

Post time: Sep-22-2022